The Ultimate Flying Experience

The Ultimate Flying Experience

Iris Infinity is the ultimate paramotor with advanced features and a complex frame geometry. We design using modern engineering technologies and use destructive testing to verify the highest standard for safety.

Our paramotors are some of the most stable and fun in flight and offer exceptional ergonomics during ground handling. We offer the highest level of weight shift with our signature swing arm system. This machine is a perfect fit for anyone from beginners to advanced freestyle and acro pilots who push paramotors to the limits.

We proudly design, test, machine, weld, coat, and assemble our paramotors and accessories in-house in the USA by local skilled employees who get paid a fair wage.

Our Quick-Release Prop Hubs

Quick-Release Prop Hub (2024)

There is good reason our Quick-Release prop hub is the most popular in the world. This year we just moved the bar even higher by adding the ratcheting mechanism from the Quickie making this the fastest Quick-Release possible.

The Quickie Prop Hub

The Quickie is a low-profile Quick-Release designed to fit into the tightest of spaces for transport. It has a real auto-locking ratcheting mechanism which cannot open without outside input. It’s the fastest way to install/remove your propeller and retain a secure locking mechanism.

Our accessories are sold and loved all over the world

Our accessories are the back bone for our company. With the help of a global network of distributors, we have been able to become the most popular Quick Release in the world and one of the highest recommended throttles on the market.

We now offer the full Dudek Paraglider Range

Unlike most manufacturers, Dudek produces their paragliders in their own in-house facility. They have decades of experience, especially in improving reflex technology. Every year they release new innovations that push our industry forward. They are perpetually improving their designs and making them suitable for more and more pilots with distinct models that have a clear purpose. Even other manufacturers that work in-house seem to be stuck in technologies that are years behind. There is good reason for why most competitions are won by Dudek wings and why their harnesses are the most desired in the industry. For these reasons, we choose to support Dudek above the rest.

Please take a moment to read about Dudek’s Technologies.

-

$3,700.00

-

$3,800.00

-

$4,000.00

-

$4,100.00

-

$4,100.00

-

$4,500.00

-

$4,700.00

Custom Works of Art

From now on, for every several standard production paramotors, we will make one special one-off work of art. These rare machines will come with higher quality components but won’t break the bank. We will catalogue how every one is coated so if one is ever damaged, the damaged parts can be replaced.

Our products are engineered using modern design tools

Let’s face it. Most paramotors today are still designed for convenience and cheap manufacturing using old-school methods without testing. Many use inadequately sized fasteners, metal-on-metal moving connections, and generally incorrectly applied engineering principles. Few manufacturers perform structural testing on their paramotors, let alone applying structural design from the beginning.

Let’s face it. Most paramotors today are still designed for convenience and cheap manufacturing using old-school methods without testing. Many use inadequately sized fasteners, metal-on-metal moving connections, and generally incorrectly applied engineering principles. Few manufacturers perform structural testing on their paramotors, let alone applying structural design from the beginning.

We believe this is unacceptable.

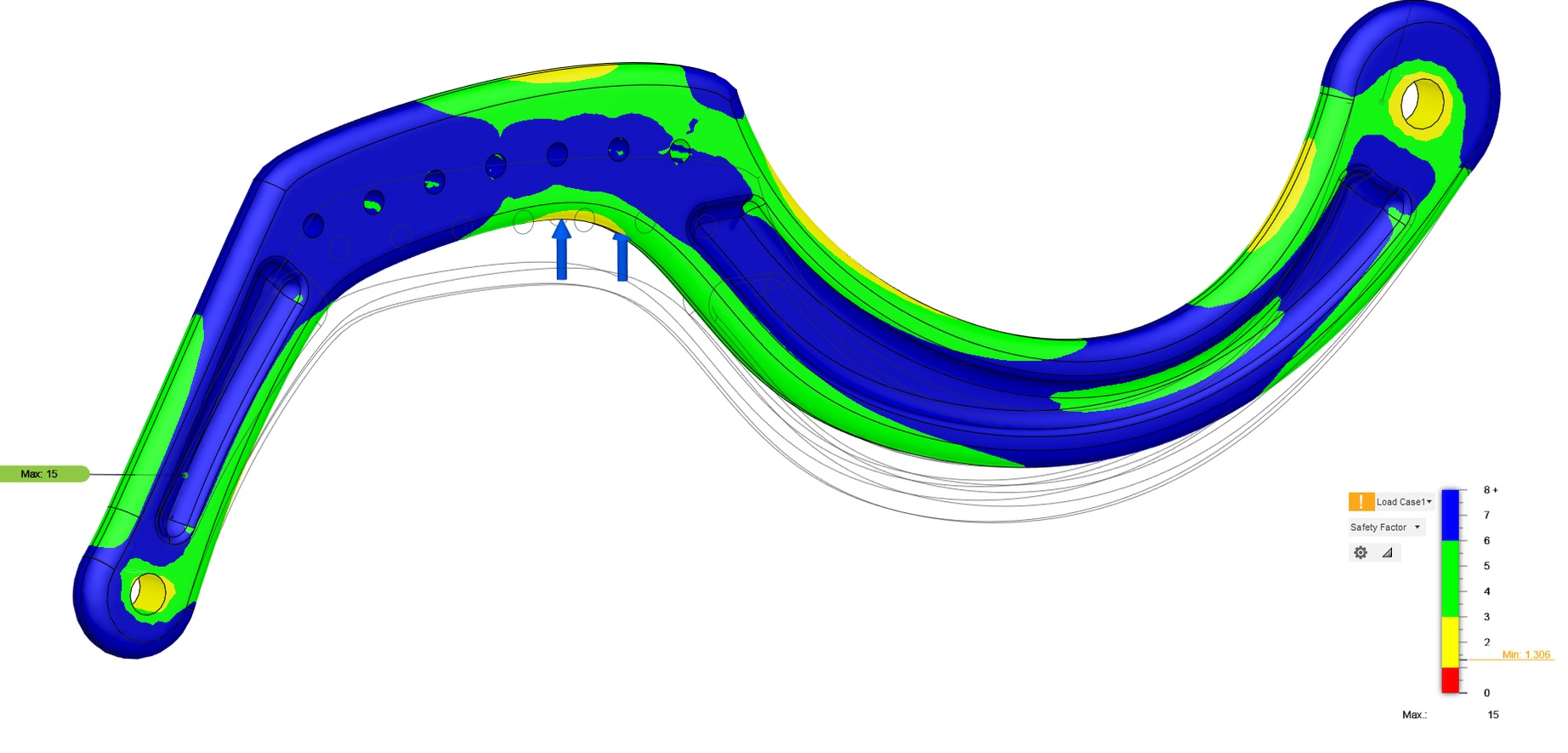

We designed the Iris Infinity using modern engineering tools and technologies. Structural components go through dozens of hours of simulations and refinement. We verify the design with real-world break testing and extensive in-flight testing. Rather than building something and seeing if it breaks in the field (especially by a customer), we set a standard and strive to achieve it.

For example, we designed our aluminum swing arms with a target breaking strength of 1600 lbs on the plate alone. With a few refinements, we overshot the engineered target to over 1900 lbs with riser offset blocks that add twisting forces. Even after the metal deformed permanently by twisting, the swing arm safely holds a load of over 1300 lbs without a notable hang angle change. This number is higher than many other swing arms on the market, even after the swing arm has failed.

Look, it’s simple

We use bushings on all moving connections

Our fasteners are adequately sized (oversized in critical positions)

Our riser offset blocks keep the carbiners nice and tidy and they are always exactly where they need to be and they don’t bang on the swing arms

Our net is strong, has full coverage and can be tensioned tightly

We use different materials based on the best material choice for a given application

We use different design/manufacturing methods based on the best choice for a given application

Our frames are modular and virtually all parts are simple and quick to replace

We use redundant safety straps

Our frame has several forms of torque compensation to fly straight under power

We have a back plate to protect your back from hitting the engine if you crash (even though it adds weight)

We care about how easy it is for you to get in and out of your seat

We want you to feel like our machine lets you connect to the wing and do exactly what you tell it instead of being a reluctant pet

We design, build and test everything in-house in the USA